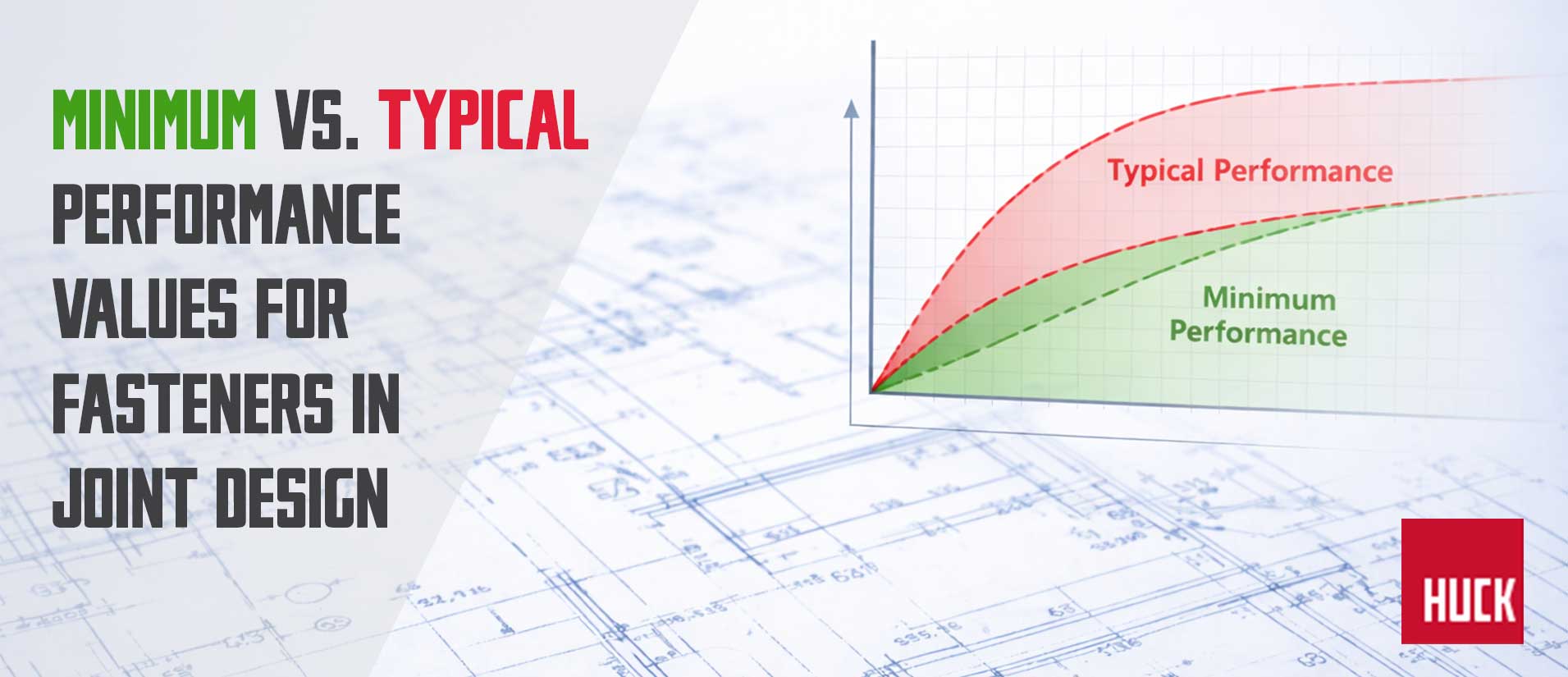

Why do some fastener manufacturers refer to minimum values and others to typical values in engineering data? In this article we’re going to explore the differences and explain how to ensure your joint is designed to the right specification.

When specifying structural fasteners, engineers often focus on published strength values such as tensile strength, shear strength, and clamp force. In the fastener industry, these values are often presented in two different ways: minimum performance values and typical performance values. This can cause confusion when working to understand the capability of a fastener. Being able to identify and understand the difference between the two is essential for safe, reliable, and compliant joint design.

Howmet Fastening Systems (manufacturers of Huck® fasteners) only ever present the minimum values. In this article we’ll explore the differences, to help you understand why brands like Huck® only ever publish minimum values.

Tip: When drawing comparisons between fasteners, Engineers should always ensure they account for differences in the way the numbers are presented (comparing like for like).

What Are Minimum Performance Values?

Minimum performance values represent the guaranteed mechanical performance of a fastener. These values are established through qualification testing and statistical control and are the basis for product certification and compliance.

For Huck® fasteners, minimum values will include:

- Minimum tensile strength

- Minimum shear strength

- Minimum preload (for lockbolts only)

In addition to the above, for Huck® fastener families covered by third party approval (like DiBt approval), you can gain insight into the minimum fatigue performance from the technical approval.

These values are conservative by design, met or exceeded by every conforming fastener, and appropriate for structural calculations and safety-critical applications.

When engineers design using minimum values, they ensure that even the lowest-performing fastener within specification will still meet the design requirements.

What Are Typical Performance Values?

Typical performance values reflect the average or expected performance of fasteners produced under normal manufacturing conditions. These values are often higher than minimums and are derived from batch testing and historical data.

Therefore, typical values may show higher tensile and shear strengths, as well as greater clamp force.

The key point to be aware of here is that typical values are not guaranteed and can vary with material batches and manufacturing variations. Typical values should not be used as the sole basis for structural design.

What can typical values be used for?

Being aware of a fastener’s typical mechanical value can be useful for a number of reasons, including:

- Comparative evaluations

- Understanding performance margins

- Supporting testing or validation activities

Why the Difference Exists

No manufacturing process is perfect. Even with tight quality control, there will always be small variations in material properties, heat treatment, and dimensions from one fastener to the next.

Minimum values account for this reality. They're established through qualification testing and statistical analysis to set a baseline performance. This is a guarantee that every fastener will meet or exceed this level, even accounting for manufacturing variation.

Typical values, on the other hand, reflect what you'll actually see in production most of the time. Since the majority of fasteners perform above the minimum threshold, typical values are higher and represent the average value for a fasteners performance.

The reason Huck® (and other responsible manufacturers) publish only minimum values comes down to liability and good engineering practice. You can't certify or guarantee an average. Design codes and compliance requirements are built around guaranteed performance, not what's "typical." By designing to minimums, engineers eliminate risk while still benefiting from the performance margin that's built into the product.

Design Implications

When designing joints with Huck® fasteners:

- Use minimum performance values for calculations. This ensures compliance with safety factors, codes, and customer requirements.

- Use typical values as supplemental information. Typical values can help explain observed performance in testing or provide confidence in design strength, but they should not replace minimums in formal analysis.

- Avoid mixing the two in calculations. Combining typical values with minimum-based safety factors may lead to underestimated risk in the design.

Best Practices for Engineers

- Base all structural and fatigue calculations on minimum published values, and ensure you understand which values your supplier is stating.

- Use typical values only for comparison, validation context, or discussion purposes.

- Consult Huck® application engineering when you need guidance on fastener selection or validation.

Conclusion

Huck® fasteners consistently deliver performance above their minimum, but proper engineering practice requires designing to what is guaranteed, not what is typical. The choice is straightforward: use minimum values for all design calculations, leverage typical values to understand performance margins and validate testing results. This approach means you'll achieve both regulatory compliance and reliable joint performance.