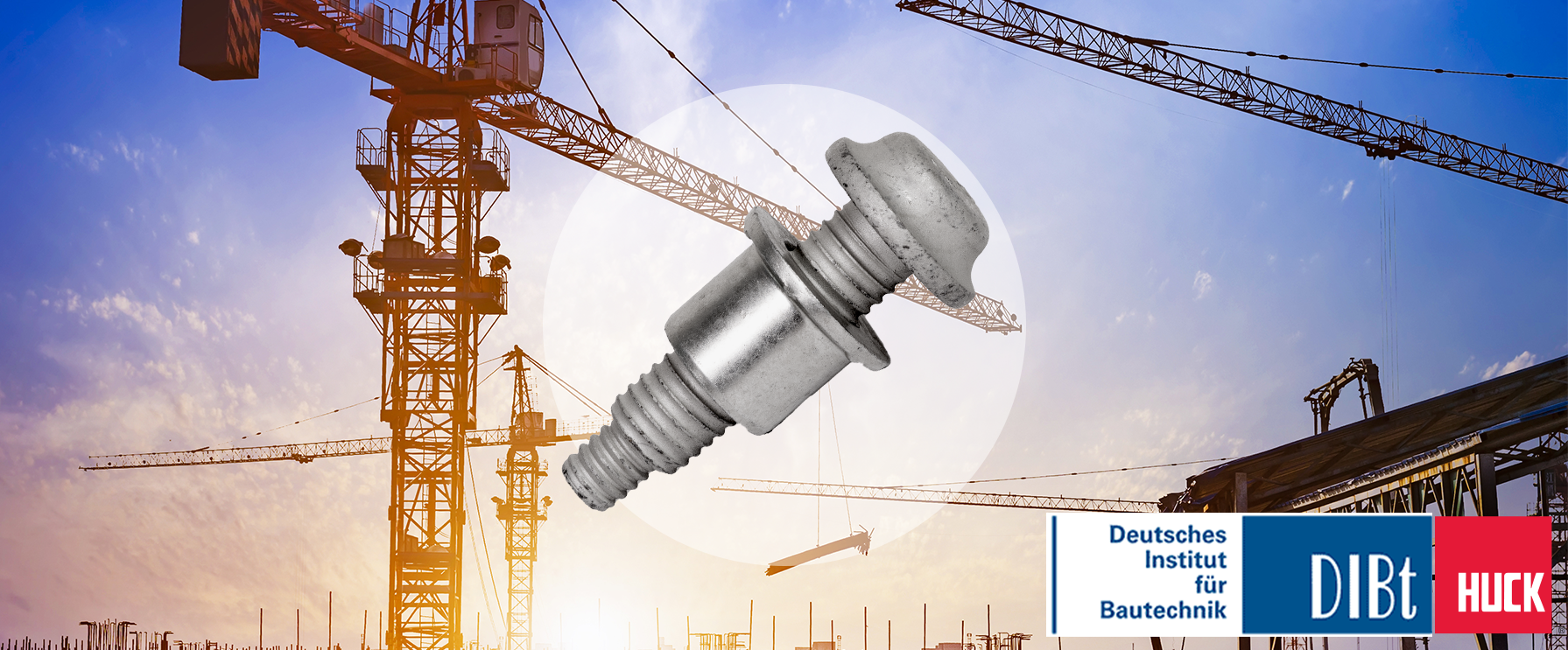

Huck BobTail lockbolts have earned a well-established reputation for strength and performance in safety-critical applications, further solidified by their longstanding DIBt approval from the Deutsches Institut für Bautechnik.

Huck BobTail lockbolts have earned a well-established reputation for strength and performance in safety-critical applications, further solidified by their longstanding DIBt approval from the Deutsches Institut für Bautechnik.

This designation signifies that BobTail lockbolts have passed a battery of stringent tests and are certified for use in a wide range of static and dynamic civil engineering applications.

The original approval, awarded in 2011, has now been extended a further two times to signify the continued confidence the DIBt places in the product's performance and quality.

DIBt Approval: A Hallmark of Quality

The Deutsches Institut für Bautechnik (DIBt) is a technical authority in the construction sector based in Berlin, Germany. It plays a crucial role in ensuring the safety of construction works by approving and assessing construction products and techniques. Earning DIBt approval is a testament to a product's adherence to the most rigorous safety and performance standards in the German construction market. A respected system of approval that although is most relevant in Germany; is also seen as a significant marker of exceptional performance around the world.

Rigorous Testing for Unwavering Performance

The approval process includes a variety of demanding tests that meticulously evaluate the fastener's ability to withstand various stresses and environmental conditions. These tests typically include:

- Tensile Strength: This measures the lockbolt's capacity to resist axial forces pulling it apart.

- Shear Strength: This assesses the lockbolt's resistance to transverse forces trying to shear the bolt.

- Preload: This determines the level of preload that prevents components from shifting or gaping against each other.

- Fatigue Strength: This evaluates the lockbolt's performance under repeated cyclical loading, critical for applications like wind turbines, bridges or crane tracks.

- Quality Control: The manufacturing process is also rigorously examined and externally monitored to ensure consistent production of high-quality lockbolts.

By successfully navigating these intricate tests, Huck BobTail lockbolts have secured the DIBt's seal of approval, solidifying their reputation as a reliable and high-performing fastening solution for critical civil engineering projects.

Mechanical Values of the Huck BobTail Lockbolt

Below is a table that denotes the mechanical properties of various size BobTail lockbolts, in terms of:

- Fv,Rk - Characteristic value of shear resistance

- Fp,C,SRB - Characteristic preload

- Ft,Rk - Characteristic value of tension resistance, values in () for G2 coating

- Ad3 - Core cross section

| Nominal Diameter | Fv,Rk [kN] | Ft,Rk [kN] | Fp,C,SRB [kN] | Ad3 [mm2] | |

|---|---|---|---|---|---|

| Lockgrooves in shear plane | Plain shaft in shear plane | ||||

|

M12 |

48,4 |

62,2 |

87,7 |

64,7 |

92,5 |

|

M14 |

66,1 |

84,7 |

120,0 |

88,3 |

126,1 |

|

M16 |

86,4 |

110,6 |

163,0 |

114,5 |

163,5 |

|

M20 |

135,4 |

172,8 |

255,0 |

179,3 |

256,2 |

|

7/8’’ (dia 22,2) |

167,2 |

212,9 |

308,3 |

218,0 |

320,5 |

|

M24 |

190,7 |

248,8 |

367,0 |

242,0 |

356,3 |

|

1” (dia 25,4) |

220,6 |

278,7 |

404,3 |

293,1 |

418,7 |

|

M27 |

242,2 |

314,9 |

477,0 |

315,0 |

452,4 |

|

M30 |

297,0 |

388,8 |

583,0 |

387,0 |

564,1 |

|

M36 |

422,5 |

559,8 |

850,0 |

561,0 |

814,3 |

A Gateway to New Opportunities

Earning DIBt approval unlocks numerous opportunities for BobTail lockbolts. Being approved by DIBt means they are suitable for use in various construction projects and applications, including:

- Structural steel connections in buildings and bridges

- Steel structures exposed to dynamic loads, like wind turbines and towers

- Seismic zones where high vibration resistance is crucial

Summary

Huck BobTail lockbolts' DIBt approval signifies a long-standing commitment to exceptional strength, reliability, and adherence to the highest safety standards - according to high standards set by the German civil engineering approval process which set the precedent for civil engineering and construction standards globally.

This prestigious designation, which has been maintained for several years, positions BobTail lockbolts as a prominent choice for a wide range of demanding civil engineering projects around the world.

To discuss how Huck fastening systems can work for your application or project, click here to request a conversation with a Huck engineer.