In the fastening world, clamp is the end game

Consistent clamp is the ultimate goal to maintain structural integrity. Without it, you risk bolt failure.

When the same torque is applied to standard nuts and bolts, there is a wide range clamp force among each fastener. The tightest bolt can end up carrying the load of 4 or 5 bolts, causing it to fail from fatigue strength. This puts even more tensile force on fewer bolts.

HuckBolts are applied with direct tension to provide consistent clamp from each fastener. Again and again. Time after time.

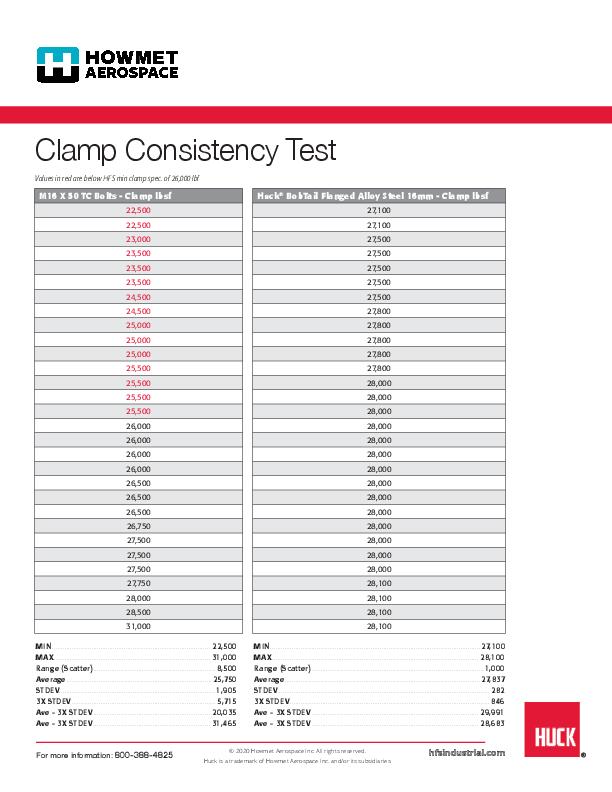

In a series of bench tests on a variety of conventional nuts and bolts, scientists found that, even when torque is consistent, clamp is not. Friction that can be caused by dust, heat, inconsistent manufacturing, and other invisible elements causes inconsistent clamp.

The consistent clamp of direct tension HuckBolts ensure a more secure joint than conventional nuts and bolts.

Watch the Skidmore-Wilhelm tests to see how HuckBolts deliver consistent clamp every time.

Which bolt will fail first?

Consistent torque does not deliver consistent clamp

Varying friction factors in the threads cause inconsistent clamp in evenly torqued-on nuts and bolts. Bolt #3 in the diagram above will fail sooner because it has a higher clamp than the other evenly torqued bolts, creating more tensile force on that one bolt. HuckBolts, however, use direct-tension to deliver consistent clamp with less than 5% range from each lockbolt, spreading the tensile load evenly between the lockbolts and providing stronger, fatigue-resistant joining power every time.

Torque vs Tension

The torque-tension relationship

Huck BobTail® lockbolts are not subjected to torsion during installation, so they can safely be taken to higher preload values than conventional bolts, which are subjected to a combination of tension and torsion forces during installation. The torsional forces from friction and geometric factors between the mating threads result in a reduction of yield and tensile strength of 10% to 20% compared to same-size BobTail fasteners.

Get in Touch with one of our Experts

Contact UsTooling Experts at 1-833-421-3805

Get in Touch

Our team of experts will be glad to answer your questions.