MIXED MATERIAL JOINING FOR NEXT GENERATION STRUCTURES

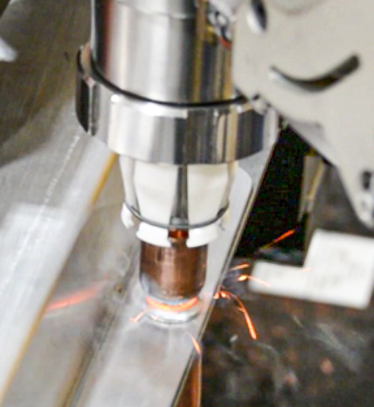

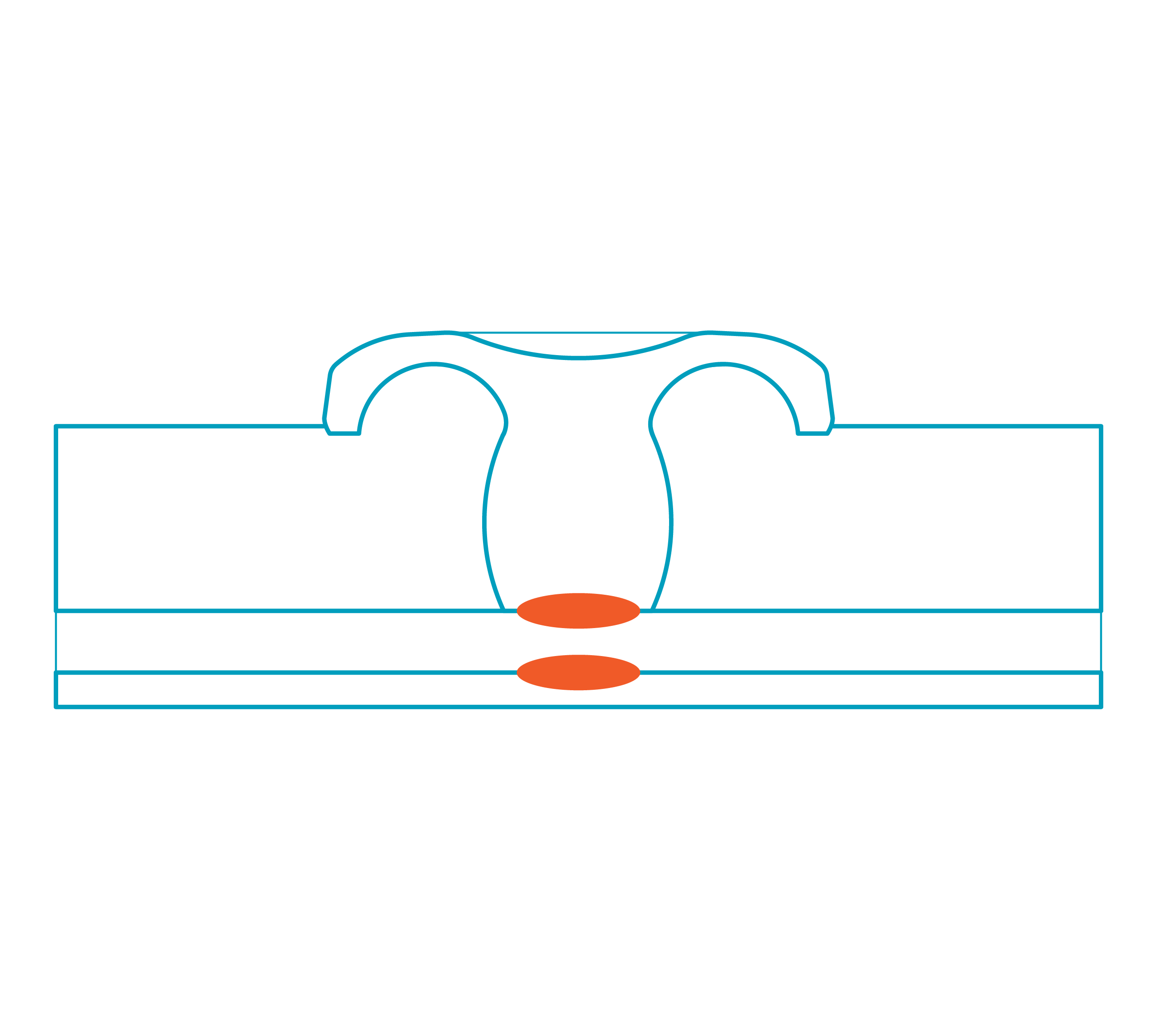

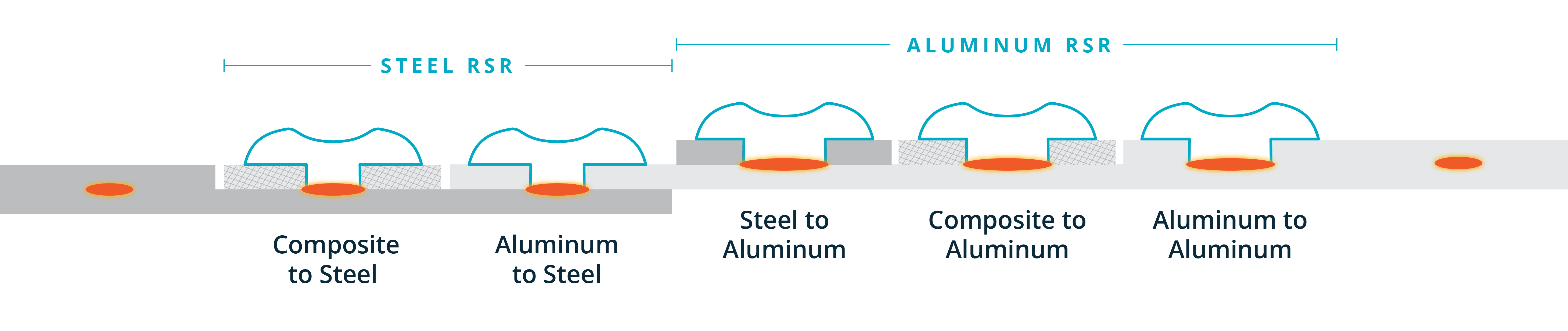

The Resistance Spot Rivet, or RSR™, is a leading technology in consumable fasteners that allows for a wide variety of mixed material joining in high speed, automated facilities. The RSR weld yields higher strengths than traditional spot welds, with the flexibility to join nearly any combination of steel and aluminum sheets or extrusions a vehicle designer may need.

A broad selection of top sheets can be accommodated with the RSR joining process, including painted and non-metallic materials. In addition, a wide range of sheet thicknesses can be joined with only a handful of rivet part numbers.

RSR joints outperform blind riveting and flow-drill screw joining in weight, strength and cost. Wherever a spot weld is used in a steel structure today, RSR can join mixed material architecture with higher strength and better compatibility, even when there are adhesive layers in the joints.

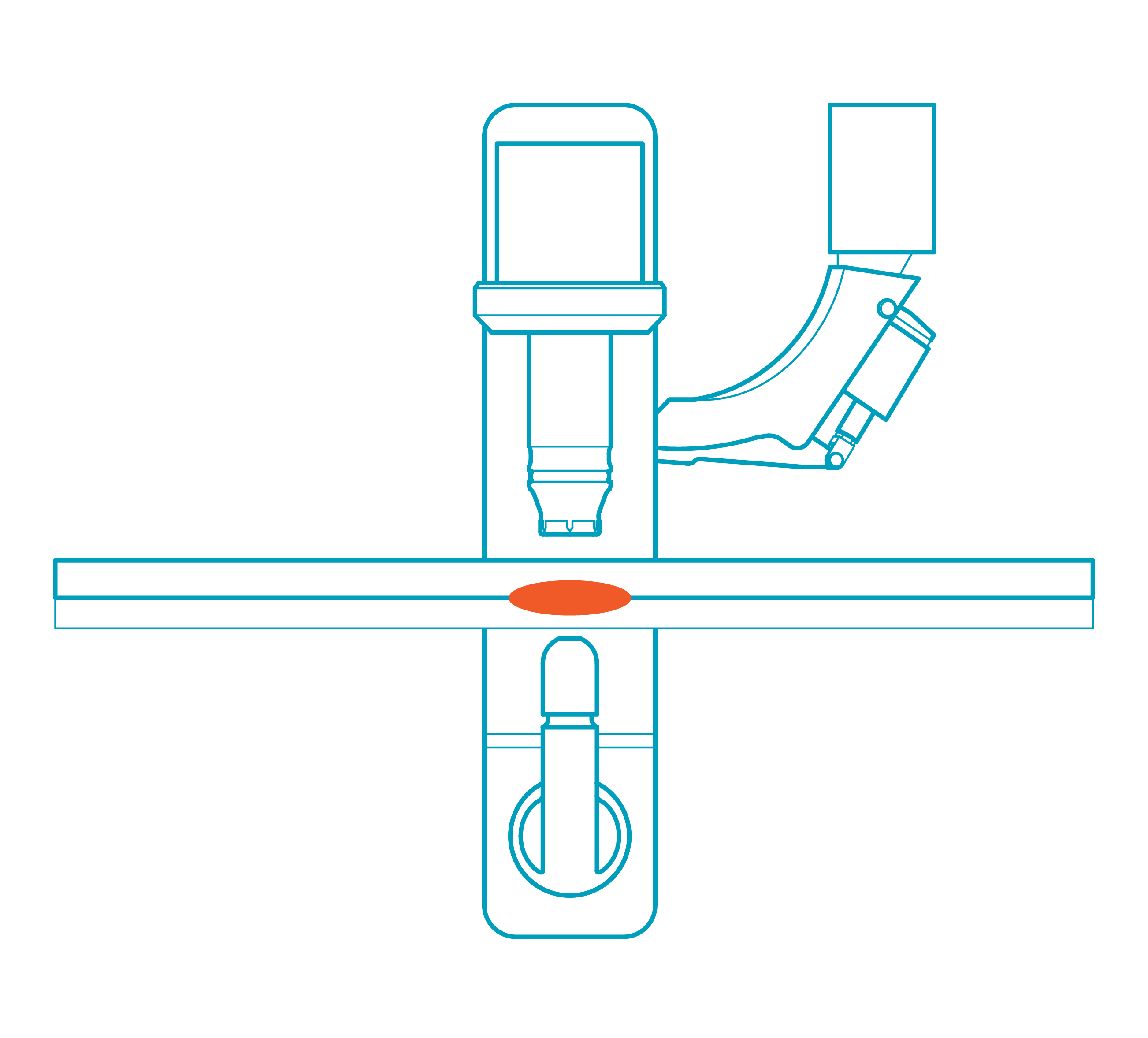

By leveraging your existing resistance spot welding infrastructure, the addition of our rivet delivery system provides you with a highly versatile assembly machine to support ever-increasing light weighting goals.

• Maintain and leverage resistance spot welding capabilities and expertise

• Seamlessly transition between resistance spot welding and resistance spot rivet joining within the workpiece

• Address a variety of mixed material joints in piloted and pre-piloted applications

• Benefit from a single-step operation – No pre-inserting of elements

• Work within the bounds of existing shop constraints

| DOWNLOAD THE RSR BROCHURE |

REQUEST RSR STARTER KIT |

RSR™ BRIDGES THE JOINING GAP OF CONVENTIONAL RESISTANCE SPOT WELDING

RSR seamlessly transitions from monolithic to dissimilar material combinations with both steel and aluminum rivets that spot-weld multi-material and multiple thickness joints, reducing capital and processing operations with just a few rivets to inventory. An aluminum top sheet can even be attached to steel without pilot holes. RSR retrofits traditional electrodes with a robust, multi-axis feed system designed for high speed, robotic resistance spot welding environments.

RSR® VS Other Multi-Material Joining Technologies

RSR outperforms self-piercing rivets, flow-drill screws and friction-bit joining in strength, speed, light-weighting and overall cost.

Downloads

DOWNLOAD THE RSR WHITE PAPER

Tooling Experts at 1-833-421-3805

Get in Touch

Our team of experts will be glad to answer your questions.