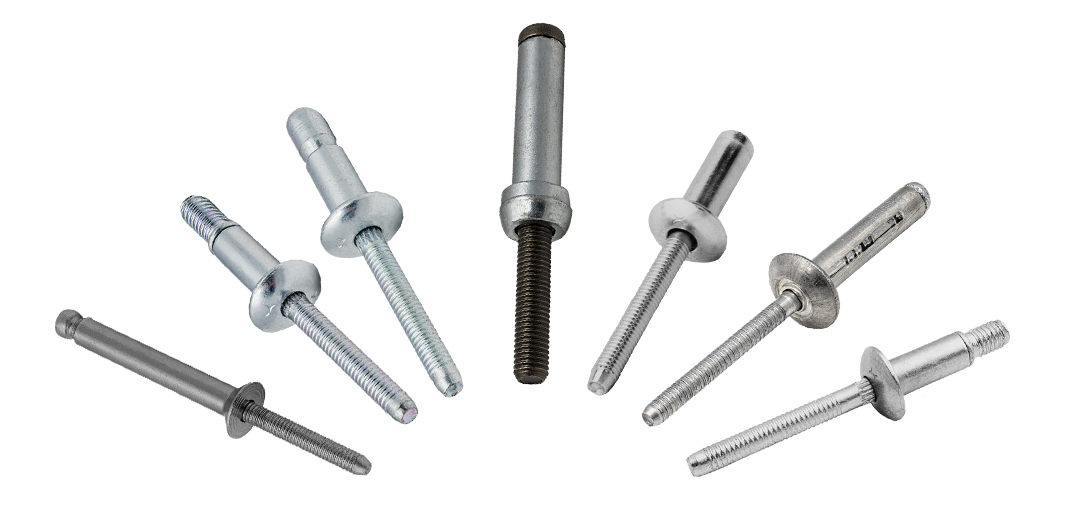

What is a Structural Blind Fastener?

A structural blind rivet is a specialised fastener designed to solve manufacturing problems, offering signficant benefits over welding and bolting.

If you're experiencing issues with vibration, long-term fastener performance and maintenance, or simply want to reduce your assembly times then Huck blind rivets can be the solution. Key benefits include:

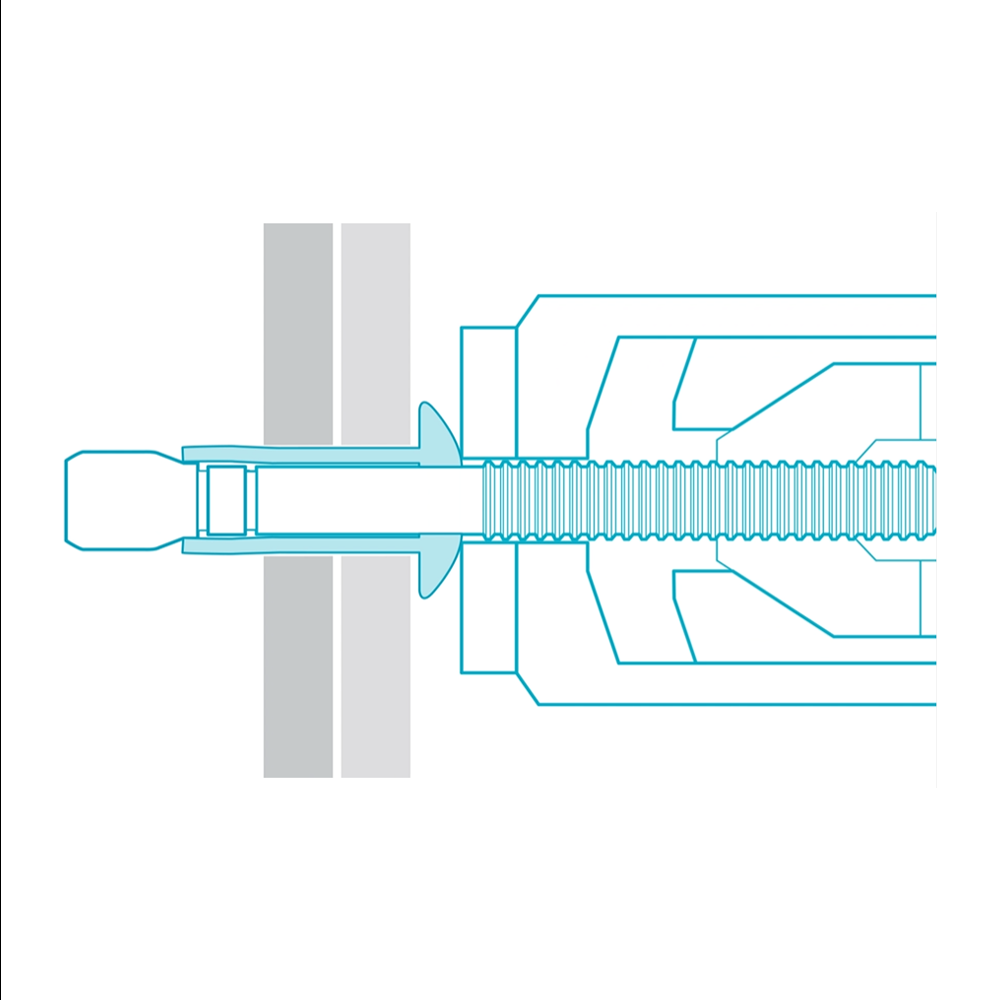

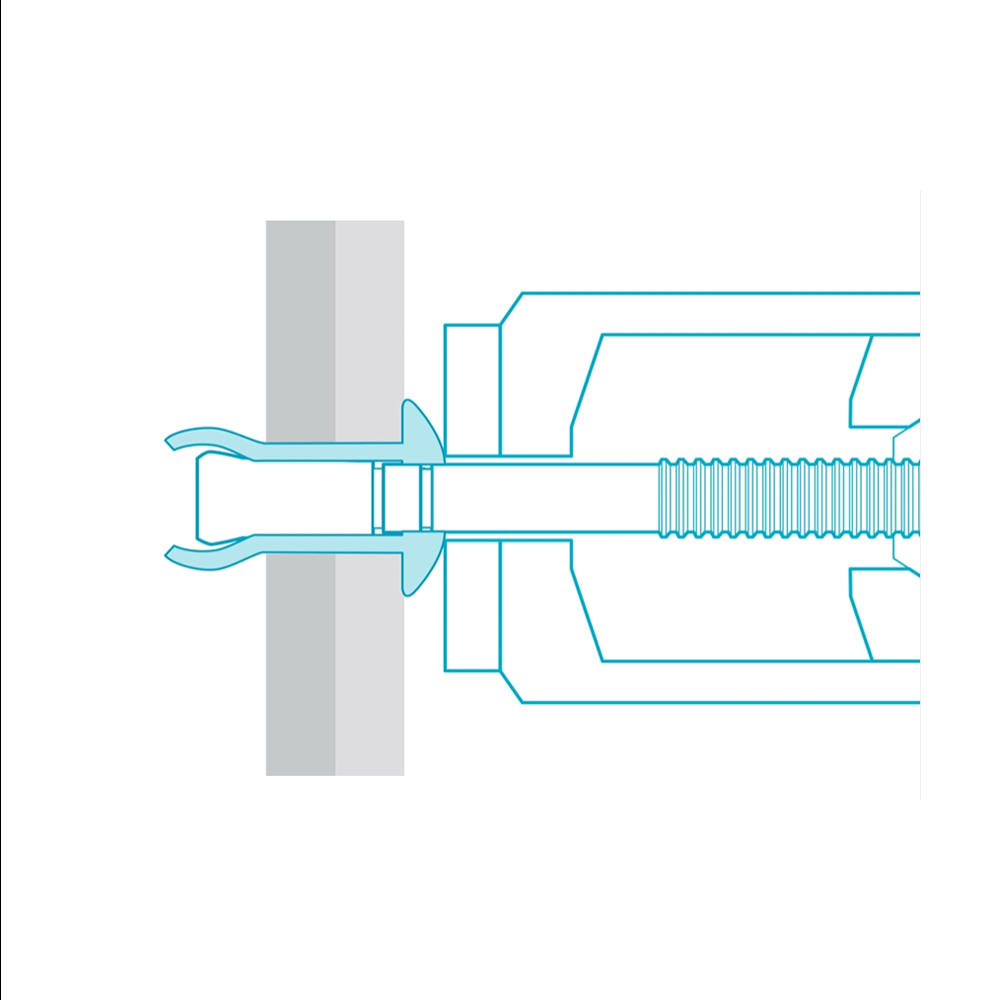

1) Improved Assembly - strucural blind rivet installations are quick, simple and efficient, reducing assembly time and increasing production throughput

2) Improved Performance - structural blind rivet joints are vibration-resistant, improving your finished product, minimising maintenance and cutting lifetime cost

In addition to the large portfolio of standard blind products the Huck team can engineer a custom structural rivet to specifically fit your application requirements. Contact us to speak to an engineer.